Vacuum Process Accelerates Perovskite Solar Cell Commercialization

A collaborative effort between global research and industry stakeholders aims to propel perovskite photovoltaics into commercial viability. While research labs primarily utilize solvent-based techniques, vacuum processes, known for their efficacy in industry, present a promising avenue for advancement. The initiative, spearheaded by Karlsruhe Institute of Technology (KIT) and the US Department of Energy’s National Renewable Energy Laboratory (NREL), underscores the potential of optimized vacuum processes in expediting the commercialization of perovskite solar cells. These findings are detailed in Energy & Environmental Science.

Stunning Advancements and Market Barriers

In the last decade, perovskite-silicon tandem solar cells have showcased remarkable progress, boasting efficiencies surpassing 33 percent, outstripping traditional silicon-based counterparts. However, despite these strides, widespread market penetration remains elusive. A critical hurdle lies in determining the optimal production method for mass manufacturing of perovskite solar cells, with solvent-based processes dominating research while vacuum vapor-phase deposition reigns supreme in industry.

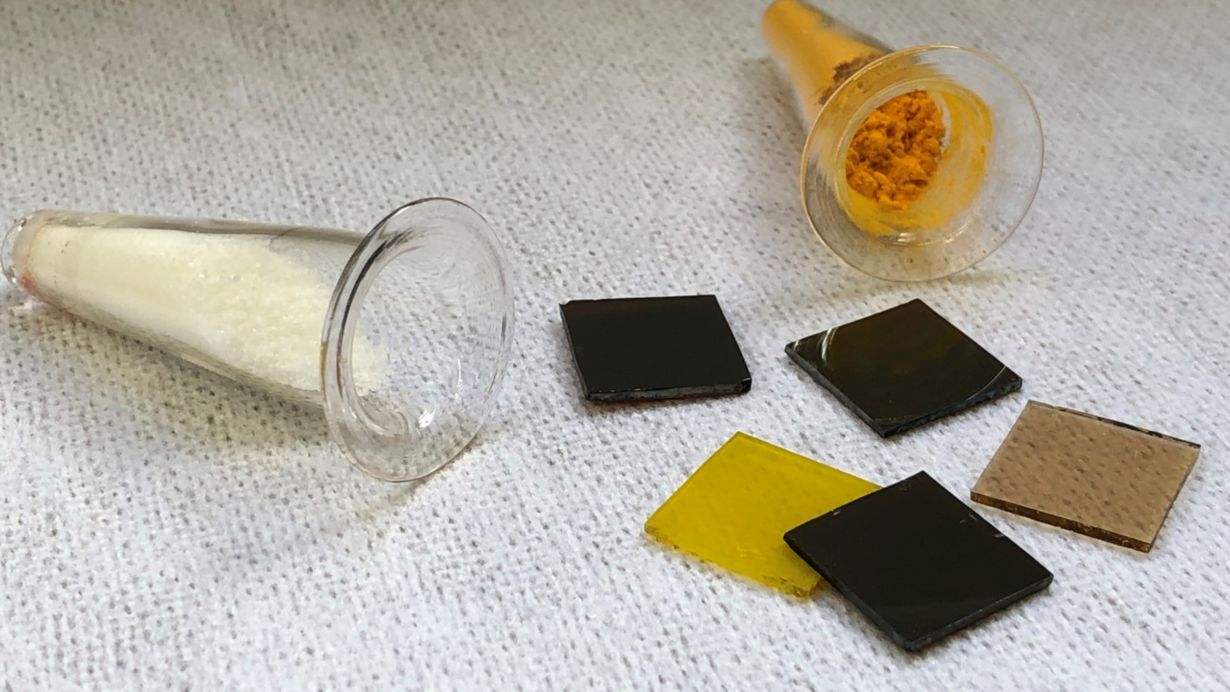

Analyzing Production Processes

The consortium, led by NREL and KIT, conducted a comparative study shedding light on the contrasting discourse surrounding production processes. While solvent-based methods dominate research due to their simplicity, efficiency, and cost-effectiveness, vacuum-based processes are significantly underrepresented despite their industrial pedigree.

Balancing Efficiency and Scalability

The study scrutinized the merits and demerits of both approaches. Solvent-based techniques offer ease of use, good efficiency, and low costs conducive to laboratory settings. Conversely, vacuum-based processes entail higher initial investments but boast competitive advantages in terms of energy efficiency, production yield, and scalability. Further enhancements in deposition quality and rate are imperative to fully harness the scaling potential of vacuum-based methods.

Future Outlook and Industry Interest

Industry’s burgeoning interest in vacuum-based processes underscores their potential for perovskite solar cell production. Despite differing from prevalent research methodologies, these techniques offer cost competitiveness and scalability crucial for commercialization.

As research endeavors delve deeper into refining vacuum processes, the prospect of leveraging their efficiency and scalability for perovskite solar cell commercialization becomes increasingly tangible. By bridging the gap between laboratory advancements and industrial requirements, this collaborative effort paves the way for a transformative shift in the solar energy landscape.

Source:miragenews.com