State-of-the-Art Manufacturing Facilities for EV Battery Systems

DURA Automotive Systems, a global leader in automotive solutions, continues to push forward in vehicle electrification with its ultramodern manufacturing facilities. The company’s new factory in Muscle Shoals, Alabama, supplies lightweight electric vehicle (EV) battery enclosures to the Mercedes-Benz battery plant in Bibb County. This advanced facility is part of DURA’s global investment in EV systems, following the launch of similar plants in the Czech Republic and North Macedonia.

Innovative Technologies for Enhanced Performance and Safety

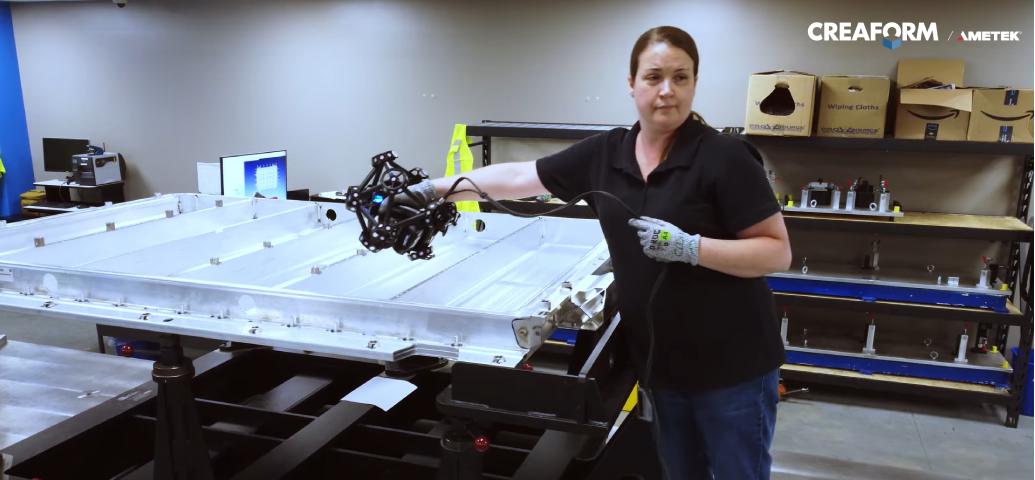

DURA’s EV battery enclosures are integral to the vehicle’s chassis, designed to protect battery modules and their associated systems. Made from lightweight materials, these structures aim to improve energy efficiency, extend vehicle range, and enhance safety. The company employs cutting-edge robotics and proprietary joining technologies to manufacture these components with precision and high quality.

Tackling Measurement Challenges with Advanced 3D Scanning Technology

In response to growing operational demands, DURA sought to enhance its quality inspection capabilities. Previously relying on a stationary coordinate measuring machine (CMM), the company faced challenges with capacity and flexibility. To meet these needs, DURA integrated Creaform’s MetraSCAN 3D|BLACK Elite and HandyPROBE systems, significantly boosting inspection efficiency and data accuracy.

Increasing Efficiency by 75% with Portable 3D Scanning

With the Creaform 3D scanners, DURA’s metrology team can now conduct inspections directly on the production floor, reducing the need to transport large structures to the metrology lab. The mobile 3D scanners offer fast, accurate measurements, allowing for a 75% increase in measurement capacity. This efficiency has also lightened the load on traditional CMM systems, which can now focus on critical inspections.

Source: foundry-planet.com