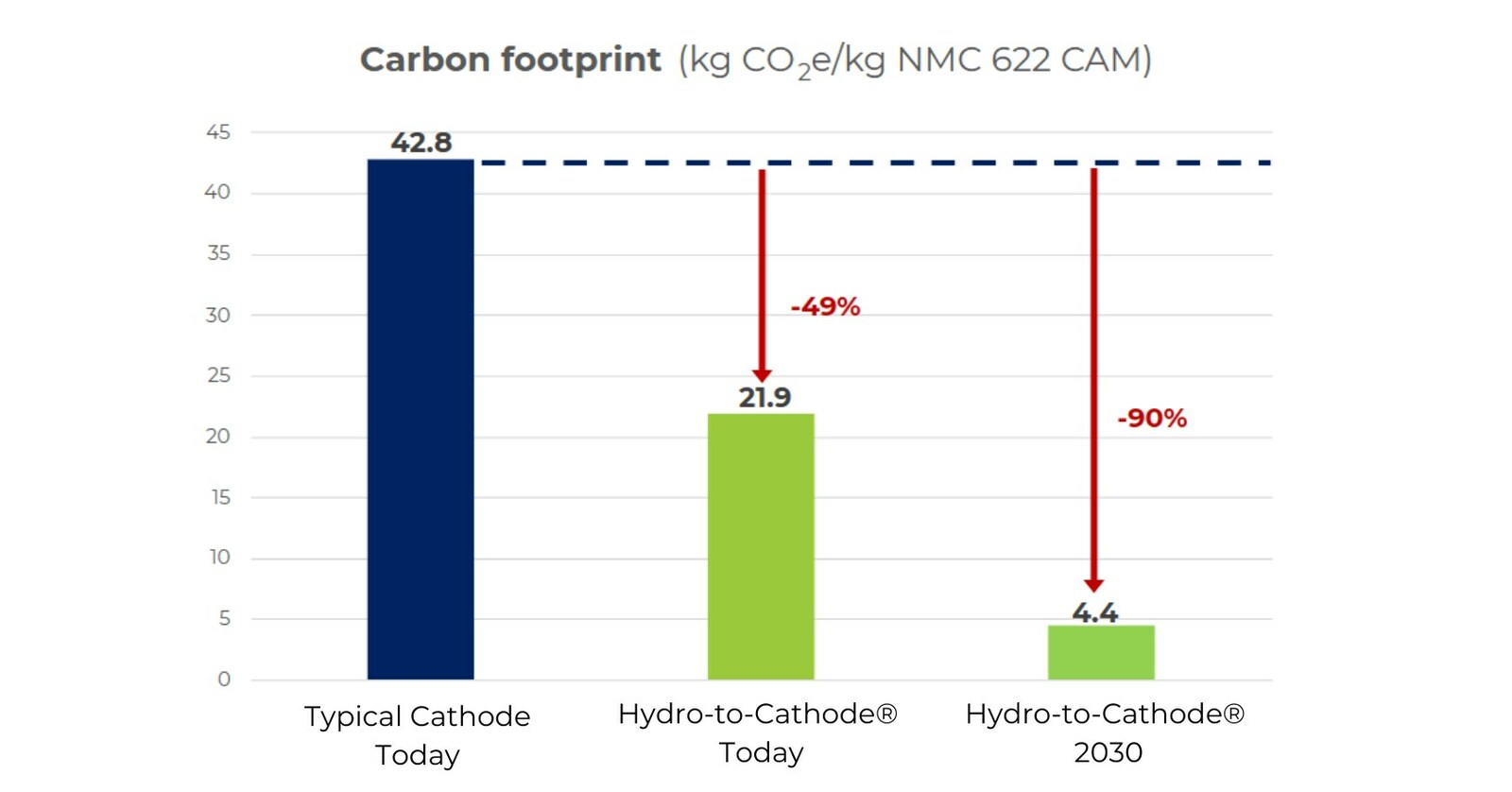

Ascend Elements, a Massachusetts-based innovator, is on a “Decarbonization Path” aiming for a substantial 90% reduction in the carbon footprint of its NMC 622 cathode product by 2030. Utilizing its patented Hydro-to-Cathode® process and recycled materials, the company currently achieves a 49% reduction in carbon emissions compared to traditional cathode manufacturing.

Green Manufacturing Practices

Ascend Elements employs 100% renewable energy in its recycling and manufacturing facilities, prioritizes rail transport for materials, and commits to responsibly sourced lithium carbonate. The company’s CEO, Mike O’Kronley, emphasizes the potential to make EV battery materials and vehicles significantly cleaner.

Life Cycle Assessment (LCA) Insights

According to a recent third-party LCA conducted in accordance with ISO 14067:2018, the production of 1 kg of Ascend Elements’ NMC 622 cathode currently generates 21.9 kg of CO2 emissions. By 2030, the company aims to bring this figure down to just 4.4 kg, showcasing a substantial reduction in carbon emissions.

Decarbonized Future Impact

O’Kronley highlights the impressive impact, stating that manufacturing 10,000 metric tons of Hydro-to-Cathode® NMC 622 using their decarbonized process could equate to removing 83,500 gas-powered cars from the road for a year.

Ascend Elements, established in 2015, leads in providing sustainable, closed-loop battery material solutions. Their Hydro-to-Cathode® technology revolutionizes lithium-ion battery material production, offering improved economics and lowered greenhouse gas emissions. As the company advances the industry towards sustainability, its commitment to reducing carbon emissions aligns with the evolving landscape of green energy policies and solar market trends.

Source:prnewswire.com