Decline Amidst Industry Challenges

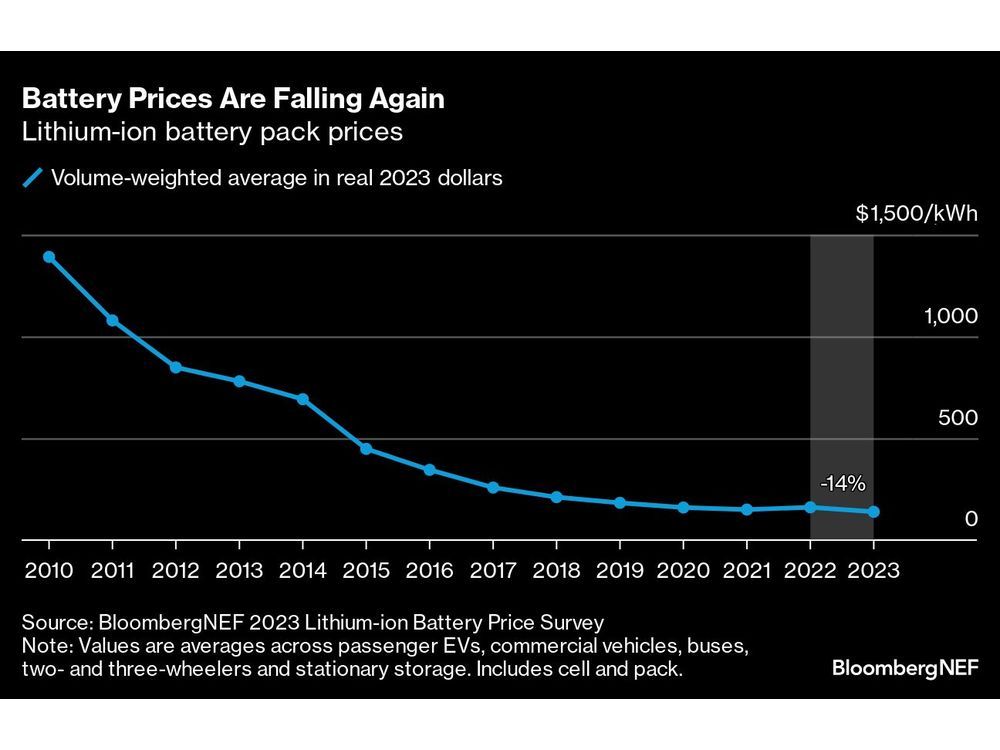

The automotive sector, striving for affordable electric vehicles (EVs), sees a silver lining as battery prices resume a long-term decline, dropping 14% to $139 per kilowatt-hour in 2023, according to BloombergNEF’s annual lithium-ion battery price survey.

Shift in Trend: Raw Material Costs Drive Reduction

Unlike historical declines fueled by technological innovation, this year’s dip is primarily credited to lower raw material costs. The significant drop in prices of key battery metals, especially lithium, since January is attributed to expanded production capacity across the battery value chain.

Global Dynamics: Oversupply and Demand

China leads in battery production, surpassing global demand, signifying global oversupply. The utilization rate of battery cell manufacturing plants decreased, aligning with automakers scaling back targets. The average battery pack price, derived from 300+ survey data points, reflects variations across sectors.

Convergence Across Sectors Indicates Industry Growth

Battery prices have converged across sectors, indicating industry maturation. While price variations exist due to sector differences, BloombergNEF foresees a consistent downward trend. The big question lies in future developments, with projections estimating pack costs at $133/kWh in 2023 and a long-term drop below $100/kWh by 2027.

Complex Path to Affordability and Price Parity

Attaining EV affordability and price parity involves addressing various challenges. Some vehicle segments, like city cars in China, are already at price parity, while others, particularly pickup trucks in the US, face hurdles due to reliance on large batteries.

Regional Dynamics and Cost Considerations

Regional battery price dynamics play a crucial role, with China offering the cheapest packs at $126/kWh. However, the US and Europe experience higher costs due to market immaturity, production expenses, and diverse applications. Localization efforts may impact prices in the short term, but industry maturity could lead to cost reductions.

Challenges Ahead: Input Costs and Continued Investment

Despite the positive trend, challenges persist. Battery prices may not consistently decline, facing bumps due to input costs and supply-and-demand dynamics. Achieving EV affordability necessitates ongoing investment in capacity expansion, research and development, and manufacturing process improvements.

Source:financialpost.com